Products

Products

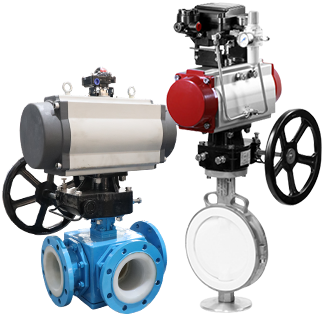

Product Overview:

ball valve, the opening and closing parts (spheres) are driven by the valve stem and rotate around the axis of the ball valve. It can also be used for fluid regulation and control, in which the V-shaped ball valve with hard seal has a strong shear force between the V-shaped ball core and the metal seat of surfacing cemented carbide, especially suitable for the medium containing fiber, small solid particles and so on.

Nominal diameter: 10mm ~ 1000mm and 1/2" ~ 60".

Working pressure: 1.0MPa ~ 16.0MPa/150Lb ~ 1500Lb/10K ~ 160K

Working temperature: -196℃ ~ 816℃.

Standards: GB, DIN, API, ANSI, JIS, BS, etc.

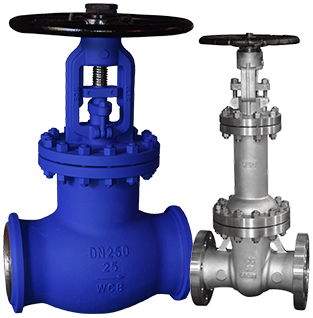

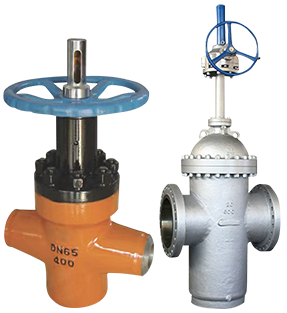

Product Overview:

gate valve is a opening and closing part of the gate plate, the direction of motion of the gate plate is perpendicular to the direction of the fluid, the gate valve can only be fully opened and fully closed, can not be adjusted and throttled. Gate valves are sealed by the contact between the seat and the gate plate. Usually, the sealing surface will be surfacing with metal materials to increase the wear resistance, such as surfacing 1Cr13, STL6, stainless steel, etc. There are rigid gate and elastic gate, according to the different gate, gate valve is divided into rigid gate valve and elastic gate valve.

Nominal diameter: 10mm ~ 1000mm and 1/2" ~ 60".

Working pressure: 1.0MPa ~ 16.0MPa/150Lb ~ 1500Lb/10K ~ 160K

Working temperature: -196℃ ~ 816℃.

Standards: GB, DIN, API, ANSI, JIS, BS, etc.

Product Overview:

Globe valve, also known as shut-off valve, belongs to the forced sealing type valve. Therefore, when the valve is closed, pressure must be applied to the valve disc to force the sealing surface not to leak. When the medium enters the valve from below the valve disc, the resistance that the operating force needs to overcome is the frictional force between the valve stem and the packing, as well as the thrust generated by the pressure of the medium. The force required to close the valve is greater than the force required to open it, so the diameter of the valve stem should be larger, otherwise the valve stem bending fault may occur. There are three types of connections: flange connection, threaded connection, and welded connection.

Nominal diameter: 10mm to 1000mm and 1/2 "to 60".

Working pressure: 1.0MPa~16.0MPa/150Lb~1500Lb/10K~160K.

Working temperature: -196 ℃ to 816 ℃.

Standards: GB, DIN, API, ANSI, JIS, BS, etc.

Product Overview:

A check valve refers to a type of valve whose opening and closing components are circular valve discs that act by their own weight and medium pressure to block medium backflow. It belongs to the category of automatic valves, also known as check valves, one-way valves, return valves or isolation valves. A filter is an indispensable device on the pipeline for conveying media, usually installed at the inlet of pressure reducing valves, relief valves, constant water level valves, and other equipment such as square filters.

Nominal diameter: 10mm to 1000mm and 1/2 "to 60".

Working pressure: 1.0MPa~16.0MPa/150Lb~1500Lb/10K~160K.

Working temperature: -196 ℃ to 816 ℃.

Standards: GB, DIN, API, ANSI, JIS, BS, etc.

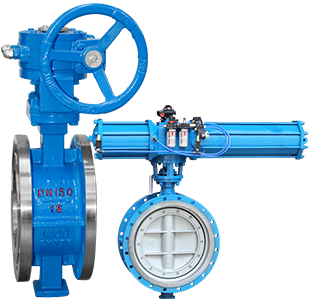

Product Overview:

Butterfly valve, also known as flap valve, is a type of regulating valve with a simple structure that can be used for on/off control of low-pressure pipeline media. Butterfly valve refers to a valve whose closing element (valve disc or butterfly plate) is a disc that rotates around the valve axis to achieve opening and closing.

Valves can be used to control the flow of various types of fluids such as air, water, steam, various corrosive media, mud, oil, liquid metals, and radioactive media. It mainly plays a role in cutting off and throttling on pipelines. The butterfly valve opening and closing component is a disc-shaped butterfly plate that rotates around its own axis inside the valve body to achieve the purpose of opening, closing, or adjusting.

Nominal diameter: 1 1/2 "~160" (DN40~DN4000)

Nominal pressure: 150LB~2500LB (0.25 MPa~42.0 MPa)

Valve body materials: WCB, LCB, CF8, CF8M, GGG40, etc

Operation modes: manual, pneumatic, electric, electro-hydraulic

Connection methods: flange, butt welding, clamp, lug

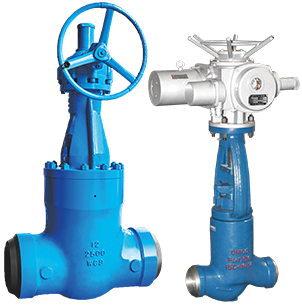

Product Overview:

Power station valves, also known as power station specific valves, are mainly suitable for cutting off or connecting pipeline media in various systems of thermal power plants. Applicable media: non corrosive media such as water and steam. The characteristics of power station valves compared to other valve products are high temperature and high pressure, unique self sealing design, and the higher the pressure, the more reliable the seal. Due to its unique performance, technical characteristics, and working conditions, the product has also developed unique features that cannot be replaced by other products.

Nominal diameter: 2 "~40" (DN50~DN1000)

Nominal pressure: 150LB~4500LB (1.0MPa~76.0 MPa)

Valve body materials: WCB, WC6, WC9, C5, C12A, A105, F11, F22F91, etc

Operation modes: manual, pneumatic, electric

Connection method: flange, butt welding

Product Overview:

A safety valve is a special valve that is in a normally closed state when the opening and closing components are subjected to external forces. When the pressure of the medium inside the equipment or pipeline exceeds the specified value, the valve discharges the medium outside the system to prevent the pressure of the medium inside the pipeline or equipment from exceeding the specified value. Safety valves belong to the category of automatic valves, mainly used in boilers, pressure vessels, and pipelines to control pressure not exceeding the specified value, playing an important protective role in personal safety and equipment operation. The safety valve must undergo a pressure test before it can be used.

Manufacturing standards: ANSI, APIDIN, BS, JIS, GB, etc

Product materials: WCB, WC6, WC1, WC9, ZGCr5Mo, ZG15Cr1Mo1VCF8, CF8M, CF3, CF3M, 12CrMoV, ZG1Cr18Ni9Ti, ZG1Cr18Ni12M02T, etc

Nominal diameter: DN10~600mm and 1/2 "~25"

Working pressure: 0.06~42.0MPa and 150lb~2500lb

Working temperature: -196 ℃~580 ℃

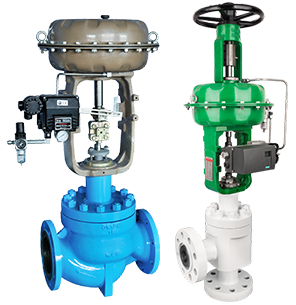

Product Overview:

Regulating valve (the final control component for adjusting process parameters) generally refers to a control valve. The control valve consists of two main components: the valve body assembly and the actuator assembly (or actuator system), which are divided into four series: single seat series control valve, double seat series control valve, sleeve series control valve, and self operated series control valve. The variations of the four types of valves can lead to many different applicable structures, each with its own unique applications, characteristics, advantages, and disadvantages.

Nominal diameter: DN20-DN200mm

Valve body material: stainless steel, cast steel, cast iron, forged steel

Control methods: switch type, regulating type, pneumatic control, electric control

Product Overview:

A drain valve generally refers to a steam trap, also known as an automatic drain or condensate drain, which is used in steam systems and gas systems. The steam trap is installed at the end of the steam heated pipeline, and its function is to continuously discharge the condensed water in the steam heated pipeline to the outside of the pipeline.

Most steam traps can automatically recognize steam and water (excluding thermal static type), thus achieving the purpose of automatic blocking and drainage.

Application scope: The product is widely used in industries such as petrochemicals, food and pharmaceuticals, and power plants, playing a significant role in energy conservation and emission reduction.

Product Overview:

Hydraulic control valve (valve for water pressure control) generally refers to the water pump control valve, which is the valve for water pressure control. The water pump control valve consists of a main valve and its attached conduits, guide valves, needle valves, ball valves, and pressure gauges. According to different usage purposes, functions, and locations, it can be evolved into remote control float valves, pressure reducing valves, slow closing check valves, flow control valves, pressure relief valves, hydraulic electric control valves, water pump control valves, etc. This type of valve should generally be installed horizontally in pipelines.

Manufacturing standards: The product is mainly designed and manufactured using international standards such as DIN, ANSI, API, JIS, BS, NF, and GB

Application scope: The product is widely used in water treatment, power, petroleum, chemical, nuclear power, construction, municipal engineering and many other fields, and is widely recognized by users.

Product Overview:

Forged steel valve refers to a valve device suitable for cutting off or connecting pipeline media on various systems of thermal power plants.

Applicable media: non corrosive media such as water and steam.

The characteristics of forged steel valves compared to other valve products are high temperature and high pressure, unique self sealing design, and the higher the pressure, the more reliable the seal. Due to its unique performance, technical characteristics, and working conditions, the product has also developed unique features that cannot be replaced by other products.

Nominal diameter: 1/2 "~4" (DN10~DN100)

Nominal pressure: 150LB~4500LB (1.0MPa~76.0 MPa)

Valve body materials: A105, LF2, F11, F304, F316, F321, etc

Operation modes: manual, pneumatic, electric, hydraulic

Connection methods: flange, butt welding, socket welding, thread

Product Overview:

Valves that use bellows as valve stem sealing elements are commonly used in situations where strict requirements are placed on valve stem sealing, such as in high vacuum applications and the nuclear industry. Use corrugated pipes instead of or in combination with the packing box on ordinary valves.

Product features:

1. Double layer corrugated pipe; 2. Easy maintenance; 3. Bellows sealed valve stem; 4. Double sealing; 5. Position indication; 6. No lifting handwheel.

Application scope:

The product is widely used in industries, power stations, exhaust gas purification plants, natural gas, vacuum devices, ammonia, hot water, refrigeration systems, heating equipment, steam systems, etc.

Product Overview:

Anti corrosion valve is a control component in pipeline fluid transportation system, which is used to change the cross-sectional area of the passage and the direction of medium flow. It has functions such as diversion, cutoff, regulation, throttling, check, diversion or overflow. Valves used for fluid control range from the simplest globe valves to various valves used in extremely complex self-control systems, with a wide variety of varieties and specifications. The nominal diameter of valves ranges from extremely small instrument valves to industrial pipeline valves with a diameter of up to 10m. Valves can be used to control the flow of various types of fluids such as water, steam, oil, gas, mud, various corrosive media, liquid metals, and radioactive fluids.

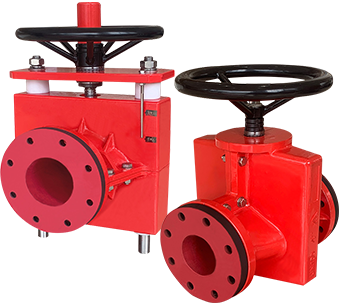

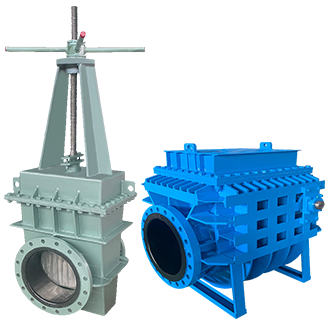

Product Overview:

Flat gate valve is a sliding valve with a parallel gate as the closing element. The closing component can be a single gate or a double gate with a support mechanism in between.

As the name suggests, a knife shaped gate valve is a flat valve plate with a knife shaped oblique cut at the bottom, which has the function of cutting off the medium, so that the valve can be closed without being blocked by the medium.

Application scope:

The product is suitable for use as an opening and closing device on transportation pipelines, venting systems, and gas storage devices such as pulp, coal ash, natural gas, petroleum, chemical, environmental protection, urban pipelines, and gas pipelines.

Product Overview:

Titanium is a highly chemically active metal. However, it exhibits particularly excellent corrosion resistance to many corrosive media. The reason is that titanium has a good affinity for oxygen, which easily reacts with oxygen to form a strong and dense pure oxide film on its surface. In many harsh corrosive media, this oxide film is very stable and difficult to dissolve. Even if it is damaged, as long as there is sufficient oxygen, it can repair itself and quickly regenerate.

Nickel is a hard, ductile, and ferromagnetic metal that is highly polished and corrosion-resistant.

Zirconium has a very low thermal neutron absorption cross-section, high hardness, ductility, and corrosion resistance. The main use of zirconium alloy is in the field of nuclear technology, such as fuel rods in nuclear reactors.

Application scope:

The product is widely used in various fields such as aerospace, shipbuilding, chemical and petrochemical, transportation, weapons, ocean, power, construction, metallurgy, medical, sports equipment, daily necessities, and light industry, and has been widely recognized by users.

Product Overview:

The oilfield specific valve is optimized and designed according to API and relevant standards, with a novel structure. The valve disc has several holes that communicate with the upper chamber, achieving self balancing of upper and lower pressures.

Manufacturing standards:

The products are mainly designed and manufactured according to international standards such as DIN, ANSI, API, JIS, BS, NF, and GB.

Application scope: The product is widely used in many fields such as power, petroleum, chemical, nuclear power, mining, natural gas, environmental protection, medicine, new materials, municipal engineering, etc., and is widely recognized by users.

Product Overview:

Liquefied gas valve is a device used to control and regulate the flow of liquefied gas. It mainly includes two types: liquefied gas globe valve and liquefied gas balloon valve. Liquefied gas valves have certain characteristics and application ranges in terms of structure and function.

The opening and closing component of a liquefied gas shut-off valve (also known as a liquefied gas valve) is a plug shaped valve disc, with a sealing surface that is flat or conical. The valve disc moves in a straight line along the centerline of the fluid. The movement form of the valve stem includes a lifting rod type (the valve stem is lifted and lowered without the handwheel lifting), as well as a lifting rotating rod type (the handwheel rotates and lifts together with the valve stem, and the nut is set on the valve body). The bellows globe valve is only suitable for fully open and fully closed, and is not allowed to be adjusted or throttled.

Product features:

Small work schedule and short opening and closing time.

Good sealing performance, low friction between sealing surfaces, and long service life.

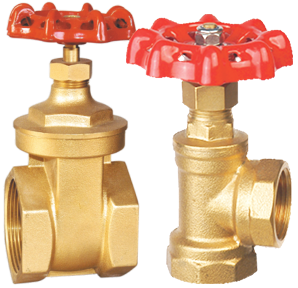

Product Overview:

Copper valves, which are valves cast with copper, belong to industrial parts and were first developed and manufactured in Ningbo, Zhejiang Province, China. In the early 1980s, Ningbo, Zhejiang took the lead in developing manufacturing processes, changing the history of long-term use of cast iron valves in China. The sand casting process was initially adopted in the manufacturing process, and in the early 1990s, it was changed to forging process. By the beginning of the 21st century, China had developed into the world's center for copper valve manufacturing.

Product Overview:

The actuator is an essential and important component in automatic control systems. Its function is to receive control signals from the controller, change the size of the controlled medium, and maintain the controlled variable at the required value or within a certain range. According to their energy form, actuators can be divided into three categories: pneumatic, hydraulic, and electric.

Application scope:

The product is widely used in various fields such as power plants, petroleum, chemical, nuclear power, mining, natural gas, environmental protection, new materials, municipal engineering, etc., and has been widely recognized by users.

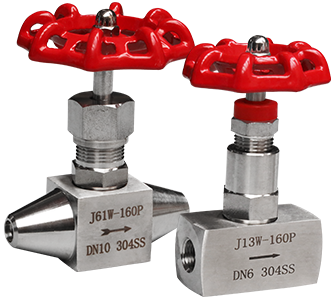

Product Overview:

Instrument needle valve is an important component of instrument measurement pipeline system, mainly including globe valve and ball valve, mainly used for opening or cutting off pipeline passage. Installation points: Before installing the valve, a visual inspection must be carried out, and the valve nameplate should comply with the current national standard "General Valve Marking" GB 12220. The outer surface of the instrument needle valve body is also subjected to atmospheric corrosion, and generally steel materials are protected by painting.

Nominal pressure: PN2.5 PN4 PN6.4 PN16 PN32Mpa

Nominal diameter: DN5 to DN25

Applicable media: various non corrosive or corrosive media such as oil, water, gas, etc

Applicable temperature: -20 ℃~+440 ℃~-70 ℃~-240 ℃ ≤ 540 ℃ ≤ 570 ℃, etc

Manufacturing materials: 20 #, 1Cr18Ni9Ti, 304, 316, 316L, 12Cr1Mov, etc

Product Overview:

The working principle of the hose valve (clamp valve) is to squeeze the internal hose through manual, electric, pneumatic, or hydraulic driving methods to achieve the function of switching and adjusting. Its characteristic advantage is that the fully permeable elastic hose has no gaps or dead corners, avoiding turbulence and wear inside the hose; When fully closed, it ensures bidirectional zero leakage closure, and the rubber hose and pipeline system are self-contained. Each opening and closing operation can be self-cleaning without blockage or dirt production. The production process of rubber hoses is divided into two types: compression molding and pure handmade. The materials used include natural rubber (black rubber), LAD special rubber (LNT), EPDM, nitrile rubber, etc. Rubber formula hoses with different properties can be customized for different working conditions, including non-standard, reduced diameter, variable diameter, through diameter, and thickened hoses.

Application scope: Mining, chemical, power, petroleum, environmental protection and other industries.

Product Overview:

SIRAT's professional rubber process involves 22 production processes, from formula design to vulcanization. Among them, the vulcanization process involves 37 production processes, from film preparation to finished product storage or assembly. We have professional rubber production and processing equipment, as well as vulcanization equipment, to ensure the high quality of our products. Standardized process operations guarantee the qualification rate of our finished products. Before the finished product is produced, the adhesion, surface quality of the lining adhesive, and thickness of the lining adhesive will be tested to ensure that the output of the finished product meets the qualified standards.